Industrial networking never stops advancing. There will always be new technologies and techniques to improve your communication, and it’s essential to keep up. One of the latest trends is industrial Wi-Fi mesh network systems.

While mesh networks have been around for a while, they have only recently been seen at an industrial scale. Now, products are available that enable large-scale industrial mesh networks, so it’s meaningful to understand what they can do for you.

What Is a Mesh Network?

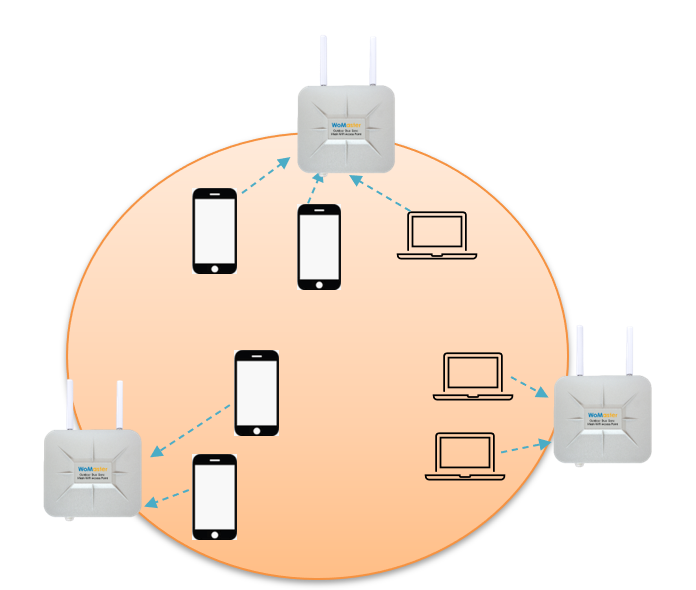

Also called ad-hoc networks, mesh networks are defined by the multipoint connections between each node in the network.

A traditional cellular network will have a single radio tower direct communication for every endpoint device, whereas the nodes of a mesh network assist each other with routing traffic.

A mesh Wi-Fi system is desirable for the redundant nature of communication they create with overlapping coverage and transmission assistance. They are particularly good when a node might be less robust than is desirable.

Perhaps the best way to think about these networks is with a simple metaphor. Say you are trying to drive to the airport in a major city. You might want to take the highway because it can handle more traffic and higher speeds than the minor roads that stretch across the city. But, if the highway is blocked for any reason, you can be stuck for a long time.

Similar to mesh Wi-Fi, if you take side roads and one is obstructed — say for construction — you can change your route and still get to the airport with little extra trouble.

In this metaphor, the mesh network is the grid pattern of city roads, and the airport is the endpoint device that connects to the internet.

The advantage of a mesh network is that the failure of any one node doesn’t really impact the overall capacity and function of the entire mesh network. Combine that with advanced automation for network management, and you can see why these networks are so compelling.

The Specific Advantages of Mesh Wi-Fi Networks

When you get into the technical details, mesh networks offer four specific advantages over other wireless network configurations.

Cooperative routing is at the top of the list. With a mesh, nodes can help each other manage traffic and send data over the network. So, if one node has a poor connection, cooperative routing allows other nodes to pick up the slack, and the endpoint experience is unchanged.

Automatic organization is also central to mesh network design. Mesh networks didn’t take off until about 2015, despite being invented in the 1980s and deliberately developed at MIT after 2003.

The reason for that delay is that Wi-Fi mesh network systems rely on high levels of automation to make proper use of their topology.

Now that the automation issues have been resolved, mesh networks require no external configuration, updating, or management from human administrators. They are entirely plug-and-play, and they are highly adaptive despite being completely automated.

Scalability is a significant benefit to investing in mesh networks. Once your mesh is up and running, you can add nodes whenever and wherever they become needed. Mesh networks can scale upward without specific design, which is why they are often called ad-hoc networks.

Mesh Wi-Fi networks are so scalable that they are now being deployed for outdoor and industrial Wi-Fi coverage. Companies like WoMaster and the WA512GM provide mesh networking tools that are designed for demanding environments.

Automated reconfiguration is the final advantage. Because mesh configuration is automated, if a node drops, it will be automatically reconfigured by other nodes in the network when it reconnects.

The same applies to the addition of new nodes. Simply connect it to the mesh, and configuration is automated.

Different Types of Mesh Wi-Fi Networks

Seeing the advantages of mesh networks makes them compelling, but it is necessary to understand the options available for mesh network design.

By and large, you can break mesh networks into two categories depending on their topology, provided you have good equipment like the Mobile Mark TMA Tactical Mesh Antenna. When looking at topology, the two categories are full and partial meshes.

Full Mesh

A full mesh network is one where every node is directly connected to every node. That sounds complicated, so consider a simple four-point network. You could arrange the nodes in a square.

You could arrange the nodes in a square, so each node has two connecting lines, and the whole mesh Wi-Fi system’s network can be reached from any point. This layout would not constitute a full mesh.

Instead, your square layout would require each node to have three connecting lines. Every possible direct connection is mapped in a full mesh network.

While this is easy to follow for a simple network with four nodes, you can see how quickly it becomes complicated when adding more and more nodes to the mesh.

This type of configuration quickly becomes expensive in terms of hardware, so full mesh Wi-Fi networks are usually only deployed for specific purposes. In general, they are used to build the backbone of more extensive networks.

For example, a full mesh could be utilized where the internet connection point is established while other parts of the network stick with a partial mesh.

Partial Mesh

A partial mesh network is where each node has multiple connections, but not all nodes are directly connected. You can think of a lattice structure as a classic example of a partial mesh.

Such topologies are cheaper and easier to build and maintain, but they have substantially less redundancy. In an industrial network, most of the mesh Wi-Fi systems will use partial topology, but it might connect to a full mesh backbone where redundancy is more important.

Mesh networks have a lot to offer industrial wireless connectivity. With their redundancy, they produce the most stable large-scale Wi-Fi networks you can build, and with their ad-hoc nature and scalability, they cater to many industrial needs.

If you’re thinking about designing a mesh for your facility or campus, Westward Sales can help. We’ll show you the best equipment for your needs, and we can even help you build an outdoor mesh Wi-Fi system that stands up to the elements while delivering all of the advantages you need.

Enhance Your Industrial Network

Whether you’re setting up a mesh network in a factory or warehouse, we understand that each environment is unique. That’s why we offer tailored solutions backed by our expertise and equipment to make your network fit for your specific needs.

At Westward Sales, we understand the complexities of industrial environments. Harsh conditions, expansive spaces, and the need for continuous operation mean that your network infrastructure must be robust and reliable.

Hence, we offer the best mesh Wi-Fi products for challenging environments. These devices ensure your network remains stable, even in the most demanding conditions. We also provide expert guidance to help you design, implement, and maintain your mesh network.

Revolutionizing Connectivity with Westward Sales

If you’re thinking about designing a mesh for your facility or campus, we can help. We’ll show you the best equipment for your needs. We’ll also help you build Wi-Fi mesh network systems that stand up to the elements and deliver all the perks.

Westward Sales stands out in the dynamic landscape of industrial Wi-Fi mesh networks. Our products are not just tools. They embody cutting-edge technology and an unwavering commitment to seamless connectivity, setting us apart as a leader in the industry. Your future begins here. So, contact us today!

Leave a Reply